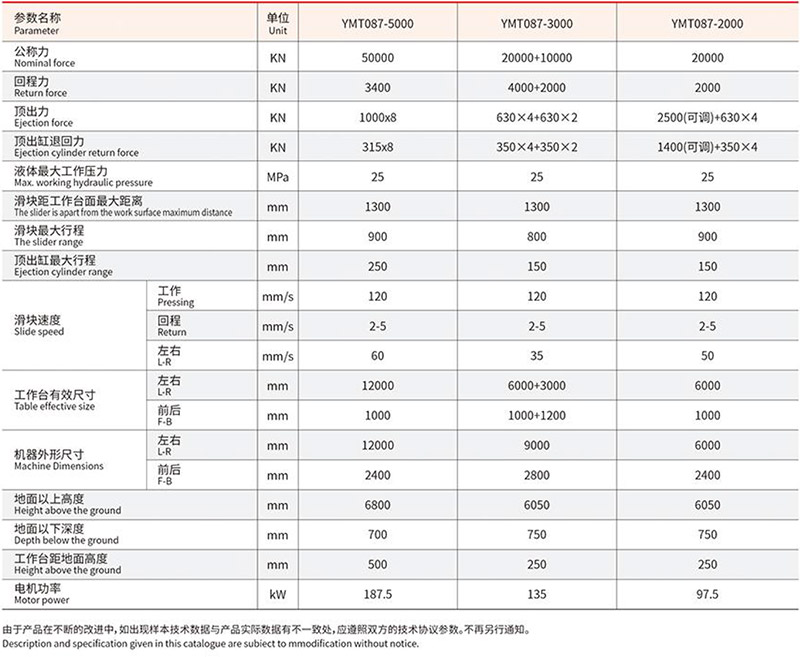

Technical Parameters:

Performance Characteristics:

This machine is suitable for automobile longitudinal beam stretching process, but also can be engaged in other sheet metal press molding as well as calibration and other processes;

The machine has an independent power mechanism and electrical system, using PLC control technology, closed-loop synchronous control system button centralized control, can achieve point, manual, semi-automatic three kinds of operation, and according to the user's different length of the product process requirements to take different program control, reduce power consumption;

The working pressure, pressing speed and stroke range of this machine can be adjusted according to the process requirements;

The machine adopts three-beam multi-column or frame structure form, the three beams are welded for aging treatment, the machine has enough rigidity and strength, and the operation space is spacious. It is easy to observe and install and adjust the molds from all sides, and the whole machine has simple structure and beautiful appearance. The hydraulic system adopts the combination of integrated cartridge system and proportional control valve, which can realize the requirements of large flow rate, high synchronization precision and high resistance to off-loading, and the structure is simple, compact, sensitive and reliable, which is convenient for fault diagnosis and troubleshooting;

The power system of this machine is upwardly mounted, which reduces the floor space of the machine. The upper beam is surrounded by a safety guardrail and is equipped with a climbing ladder for easy installation and maintenance;

Normal control system or servo control system can be used.

客戶使用現(xiàn)場